Custom Industrial Products

Vinyl Technology serves as a custom industrial goods manufacturer that builds heavy‑duty sewn and welded fabric‑based products for industrial and commercial clients. We deliver custom industrial product manufacturing with a focus on material choice, stitching, or RF‑welding method and quality control.

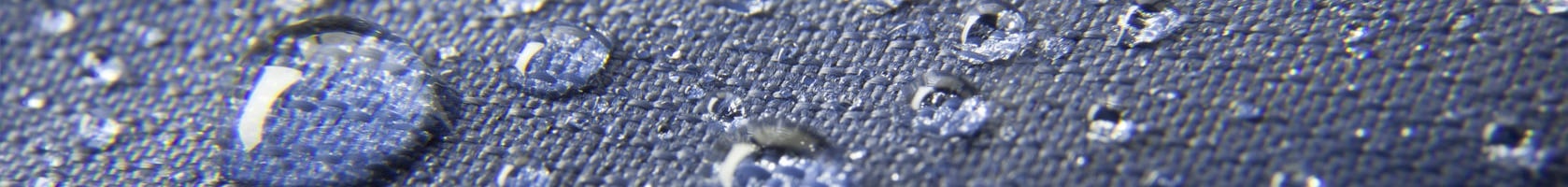

Our team works with materials like PVC-coated polyester, vinyl‑coated fabrics, and coated films that must meet tough demands around durability, weather resistance, chemical resistance, and tear strength. These products go beyond simple tarps or bags. We produce gear like cargo bags, custom fuel bladders, hazmat suits, and other items that require precision sewing or welding.

As a custom industrial product manufacturer with decades of experience in industrial sewing and technical fabric assembly, Vinyl Technology has skilled craftsmanship with industrial‑grade machines. Have a project that requires small‑batch prototypes? Maybe large‑volume runs? VTL handles material selection, stitch‑type or heat‑seal choices, and fabrication. That means you receive industrial products built for performance, longevity, and reliability from a partner that understands how to build for tough conditions.

Materials

PVC/Vinyl

Polyethylene

Polyurethane

CPE

EVA

TPU

Mil-Spec Materials

Polyurethane Coated Fabrics

Vinyl Coated Fabrics

Industry

Custom Industrial Product Manufacturing – DRIGUARD®

VTL’s DRIGUARD® environmental covers are custom-made to customer specifications. These custom industrial products are manufactured and used in a variety of conditions to protect products of all sizes from weather or ambient conditions during transport. They are often kept under positive pressure to maintain maximum protection. These are just one of the custom industrial goods manufactured through Vinyl Technology.

Product Features

- Protects against all weather conditions

- Can be kept under positive pressure with an external air source

- RF welded for maximum seal reliability

- Sizes range from small to very large. Let VTL know your needs.

- VTL can recommend or help you select materials

Why Choose Vinyl Technology for Custom Industrial Goods Manufacturing

Vinyl Technology began producing custom industrial fabric products over 40 years ago in support of aerospace and defense clients with complex sealing, strength, and material demands. Over time, that expertise expanded into transportation, medical, and environmental applications that require exact tolerances and tested durability.

As a custom industrial product manufacturer, we’ve built containment bladders for aircraft fuel systems, large-scale industrial covers for outdoor storage, and sewn PVC components for medical environments where clean handling matters. Each item is produced in our California facility under quality standards that meet government, military & private-sector specs. We support both short-run custom work and high-volume orders, all built to meet real-world demands with repeatable performance.

Frequently Asked Questions About Custom Industrial Product Manufacturing

What does “custom industrial products manufacturer” mean?

A custom industrial products manufacturer means a company that builds fabric‑based or industrial‑grade products to meet exact specifications rather than offering off‑the‑shelf solutions.

Can Vinyl Technology handle small‑batch or prototype orders?

Yes. Custom industrial product manufacturing supports both one‑off prototypes and large‑volume runs, depending on your needs.

What industries can benefit from custom industrial goods manufacturing?

Industries like medical, defense, transportation, environmental containment, and industrial storage can benefit. Any application needing strong, tailored fabric- or film‑based products.

How does custom industrial manufacturing differ from mass‑produced products?

Custom industrial goods manufacturing delivers products built to spec for strength, durability, and function rather than generic standards. Quality control and material selection are geared toward performance and longevity.