Quality Assurance and Reliability Testing

To ensure compliance with customer specifications and to industry standards, VTL has highly skilled and qualified quality assurance staff. They include Six Sigma-certified Green and Black Belts to ensure a comprehensive approach to quality assurance throughout the value chain.

The quality assurance engineers facilitate structured new product and process introductions, comprehensive root cause analysis, DOE (Design of Experiments) studies, FMEA studies, and more. Since 2014, VTL has implemented Lean-Six Sigma methodologies to improve operations.

VTL’s Quality System is currently certified to AS9100D [pdf]

What You Get with VTL

Certifications

Vinyl Technology, LLC complies with standards required by the US government and Department of Defense that include the National Institute of Standards and Technology (NIST), The International Traffic in Arms Regulations (ITAR), Defense Federal Acquisition Regulation Supplement (DFARS) to the Federal Acquisition Regulation (FAR), STANAG 4671 and MIL-STD-6396. VTL can also fabricate products that comply with the Berry Amendment when required.

VTL’s Quality System is currently certified to AS9100D and ISO9001:2015. Since 2014, VTL has implemented LEAN Manufacturing practices, Six Sigma, and Kaizen methodologies to improve operations. VTL is a FDA Registered manufacturer of medical products.

Continuous Process Improvement

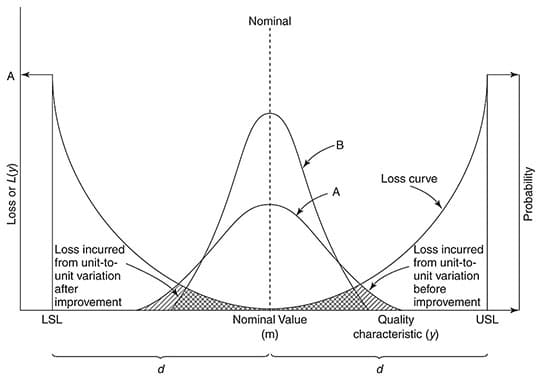

At VTL we are continuously looking to improve our process. We believe that reducing variation in our processes will lead to improved process control and fewer defects.

Six Sigma Problem-Solving Approach

VTL employs Six Sigma as a quality management methodology used to discover and eliminate defects. The goal is to streamline quality control so there is little to no variance throughout.

Design of Experiment Studies

VTL uses DOE as a systematic method to determine the relationship between factors affecting a process and the output of the process. An understanding of DOE requires knowledge of statistics and experimentation.

Kaizen

We incorporate the Japanese methodology called “Kaizen.” At VTL we are continuously looking to improve our process. We believe that reducing variation in our processes will lead to improved process control and fewer defects.

Poka-Yoke

Poka-yoke is a Japanese concept loosely adapted from the more familiar English term “idiot-proof.” Rather than assume the worker is an idiot who needs to be protected from themselves, poka-yoke instead refers to the act of avoiding a really bad move.

Continuous Testing and Inspection:

At VTL we implement continual quality testing to ensure peak performance and are trusted by both government and leading industrial, medical, and aerospace, and defense companies.

Customer Specified AQL Level Inspections

VTL incorporates standard acceptable quality limits to our QA system. VTL can also support products that demand a more robust AQL, depending on the application.

In-Process Testing

In-process testing is performed on products during the manufacturing process to ensure it is being manufactured to customer specifications. Inspection and performance testing is performed by quality control specialists prior to shipping.

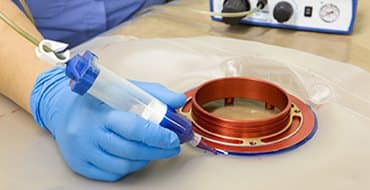

Inflation, Vacuum Testing

VTL has extensive experience in inflation and pressure loss testing, water- and fuel-leak testing, and many other types of in-line tests deemed critical for product application.